nVent RAYCHEM takes control & monitoring (C&M) product capabilities to the next level by further enhancing connectivity of electrical heat tracing (EHT) with process control systems (DCS) to allow open communication between systems, enhanced data integration and real-life monitoring. Thanks to RAYCHEM’s new user-friendly solutions – the RMM-DI module and the Touch1500-to-DCS system industrial application – operators can lower installation cost, improve process reliability and make operations on field easier and more productive than ever before.

Reduced installation and maintenance costs

Minimizing installation and maintenance time on field, especially in extreme weather conditions, is crucial. Remote monitoring is not only required to make the supervision of field devices safer for members of staff but also to make these processes more efficient and cost-effective.

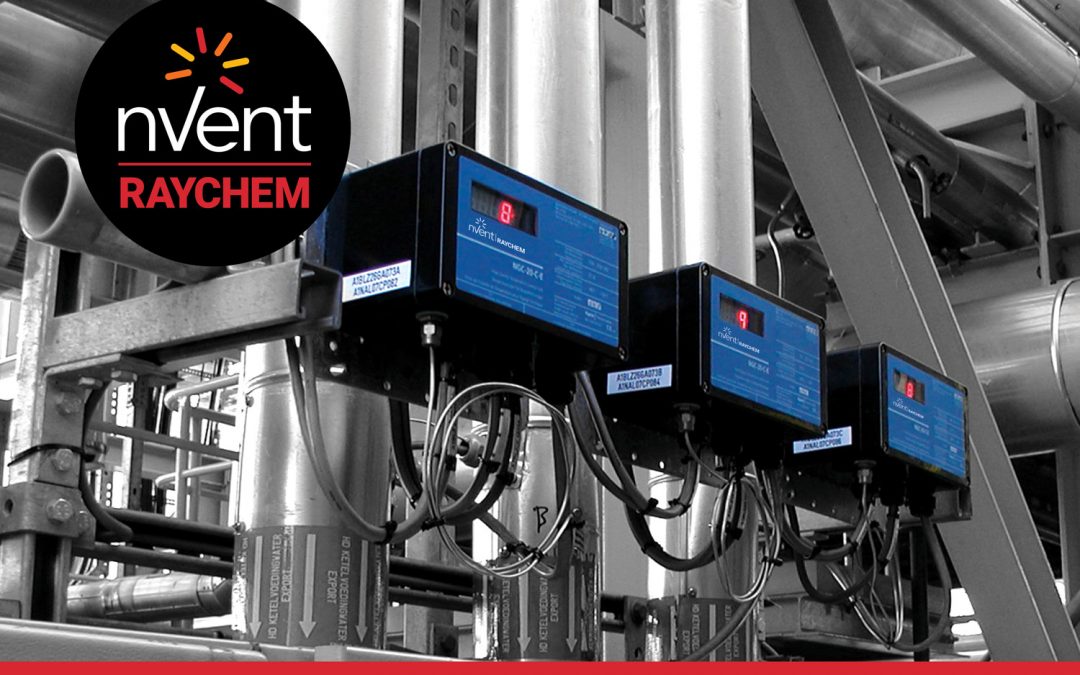

The new RAYCHEM Remote Monitoring Module for Digital Inputs (RMM-DI) is a multiplexing solution, fully integrated and supervised EHT system that transfers digital heat trace data to a central monitoring location from any field devices. With 15 digital inputs and multiple RMM2-DI units that can communicate with a single user interface, sensing cable quantities can be reduced and installation costs and time can be drastically decreased. Additionally, real-life monitoring, for example, of the position of each power circuit breaker in electrical field panels can reduce site interventions and increase uptime. The module is designed for safe area application and ATEX Zone2 application, with a robust housing that withstands hazardous climate with ambient operating temperatures from -40° to +60°C.

Improved process reliability and plant safety

To expand the capabilities from a controlling point of view, operators need advanced data integration to give them full visibility over all levels to know the status of each system at all times.

The RAYCHEM Touch1500-to-DCS software capability transfers heat trace data into process control, power management and maintenance management systems to allow simultaneous monitoring of multiple systems at the same platform. This not only improves the plant’s operational reliability, but also helps to make informed decisions or foresee and prevent potential system shutdowns early.

Using a customizable mapping tool, the Touch1500 software, allows operators to define relevant controller data from control systems and choose the format that it should send to the control room. The system offers maximum flexibility in how data can be displayed, resulting in high transparency at all levels and quicker decision-making when it matters.

“Integrating nVent Thermal Management’s heat tracing Control & Monitoring solutions with DCS systems and offering ‘data à la carte’ are important steps to accelerating the realization of Industry 4.0.”, explains Robert Kuipers, product manager Europe, Middle East & Africa at nVent Thermal Management. “Plant operators today drive the industry, they want to push production to a maximum and be on top of what’s happening at all times, so enhancing system integration and information transparency was essential to ensure we were meeting the demands of our customers.”

For further information about nVent RAYCHEM Control & Monitoring solutions, including technical data, visit: https://www.nvent.com/RAYCHEM