The NIMU non-invasive signalling unit ensures the highest leak-tightness and reliable monitoring of the rupture discs used. The new GRX graphite rupture disc also ensures permanent leak-tightness in normal operation, due to a specifically developed coating, even at extreme temperatures. Additional highlights of the largest German rupture disc manufacturer are high-pressure rupture discs, the REMBE CAE (Computer Aided Engineering) Service and the REMBE Authorized Partner Program, as well as the REMBE Rush Order Service, which promises the instant production and delivery of rupture discs.

NIMU, the Non-Invasive Monitoring Unit

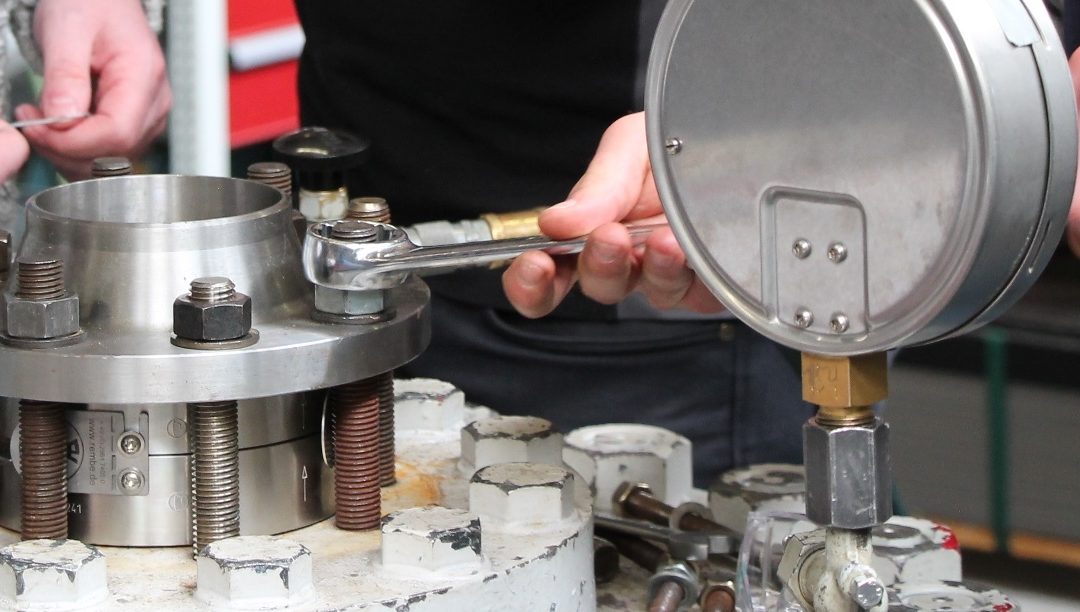

Conventional burst indicator devices require cables to be mounted on the rupture disc, which must then be routed out through the rupture disc holder. This is not the case with the NIMU. A signalling indicator is attached to the rupture disc during its manufacturing. The actual sensor is screwed into a blind tap in the rupture disc holder, where it monitors the position of the signalling indicator on the rupture disc. This means that the cable only starts outside the rupture disc holder.

After a pressure relief, and the associated opening of the rupture disc, the outlet part of the rupture disc holder must be removed, the rupture disc replaced, and afterwards the system can be put back into operation. Gone are the days, when the signalling cables have to be routed again to the respective switching box. This allows the colleagues from the electrical department to devote their attention to other tasks.

Additionally: The process is absolutely leak-tight. The blind tap in the holder replaces the otherwise necessary continuous holes. The absence of perforated gaskets (for conventional signalling cable holes in the holder) means that the utilized gaskets cannot become porous, thus preventing an escape of the process media.

Graphite rupture disc GRX with PyC coating for extra-long temperature resistance

This rupture disc has been developed for processes with corrosive media, low pressure and temperatures of between -180 °C and 1,500 °C.

The GRX is available with a synthetic resin coating (process temperatures up to 200 °C), as well as a PyC coating, developed specifically for the GRX (temperatures above

200 °C). With the PyC coating, the rupture disc holds significantly longer at very high temperatures, while remaining permanently leak-tight. Rupture discs with a coating made of synthetic resin would no longer be able to offer this leak-tightness at temperatures far above 200 °C.

With an operating pressure ratio of up to 90 % and burst tolerances of +/- 5 %, the GRX is usable for rupture pressures from 0.02 bar. Optionally, a vacuum support can be integrated, which is installed without adhesive (which melts at very high temperatures). The GRX is also available with a burst indicator, upon request. The installation occurs directly between the flanges. So far, the GRX has already been installed in various reactors, tanks, glass containers and other system parts in the chemical and petrochemical industry.

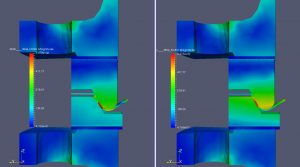

REMBE high-pressure rupture discs – design change extends service life

Since the REMBE engineers modified the standard rupture disc design so far across manufacturers, the high-pressure rupture discs by REMBE have been significantly more durable, as the welding seam of the rupture disc is not stress as usual, in terms of sheering and bending, but only in terms of pressure. Through the geometric separation of the stress spike and the welding seam, the rupture disc is more long-lasting and allows the lowest rupture tolerances of up to +/- 3 % at pressures of up to 5,000 bar and temperature of up to 400 °C.

REMBE CAE (Computer Aided Engineering)

As a relatively young discipline, CAE has been on the advance for a considerable period of time, after the aviation and aerospace industries, as well as the automotive industry, industrial mechanical engineering is now also discovering these development and calculation methods more and more for itself. The advantages are obvious: through the simulations and calculations using CAE, development processes are accelerated and expenditures are drastically reduced for prototypes.

In view of the system elements and the related pressure safeguarding devices, strength, leak-tightness and flow analyses, as well as temperature profiles, are particularly relevant. REMBE is the first rupture disc manufacturer worldwide to offer relevant CAE services. For systems operators, it is therefore not necessary to involve an engineering firm or similar service providers, which specialise in CAE. In conjunction with the company’s high-quality products, its customers receive a complete solution with real added value: The CAE calculations of the specialists for pressure relief guarantee the most reliable results, which subsequently flow into the customised production of the rupture discs.

“For a long time, we have no longer been a pure product supplier. Our specialists are constantly on site with customers, inspect the system together and develop customised, efficient safety systems, also on the basis of our CAE tools.” explains Stefan Penno, Managing Director of REMBE GmbH Safety + Control.

“Originally, the CAE was taken up for internal purposes. On the basis of the positive feedback from many customers, we how now decided to intensify these services.”

At present, the available customer enquiries are particularly related to strength calculations and leak-tightness verifications. However, the CAE professionals at REMBE are already working on many additional services.

REMBE Authorized Partner Program

The best pressure relief is ineffective, it is not correctly installed, maintained or replaced. Therefore, regular training of own staff or the selection of the right service company are crucial. Not just to avoid monetary losses due to damaged relief devices, but particularly to guarantee the safety of the system and the employees.

The REMBE Authorized Partner Program is aimed at operators, as well as workshops and service companies, which are responsible for the installation, maintenance and servicing of rupture discs. In addition to regular training courses, the program events offer the participants the opportunity to compare notes. Service companies can have themselves audited. Presently, the Nopa Industriearmaturen GmbH, Bilfinger Maintenance GmbH and InfraServ GmbH & Co Gendorf KG companies are certified as REMBE Authorized Partners in Germany.

REMBE Rush Order Service – Instant production and delivery of your rupture disc

Depending on the corporate philosophy and personal preference of the persons responsible, the spare parts warehouses of individual operations are filled to a different extent. Anyone who wants to play it safe, also keeps the appropriate pressure relief devices in stock. Or, uses the REMBE Rush Order Service. This guarantees the instant production and delivery of a rupture disc.

About REMBE

REMBE a global specialist for explosion safety and pressure relief. The company offers customers cross-industry safety concepts for systems and equipment. All products are manufactured in Germany, and meet the demands of national and international regulations. The customers who purchase REMBE products are among the market leaders of various industries, including the oil and gas, food, wood, pharmaceutical, chemical and petrochemical industries.

The technical engineering expertise is based on more than 45 years of application and project experience. As an independent, owner-managed family company, REMBE combines expertise with highest degree of quality, and is also actively engaged in various professional bodies worldwide. Short alignment routes enable the achievement of quick responses and customer-specific solutions for any kind of application: from the standard product, all the way up to high-tech special designs.

www.rembe.de sandra.drawe@rembe.de