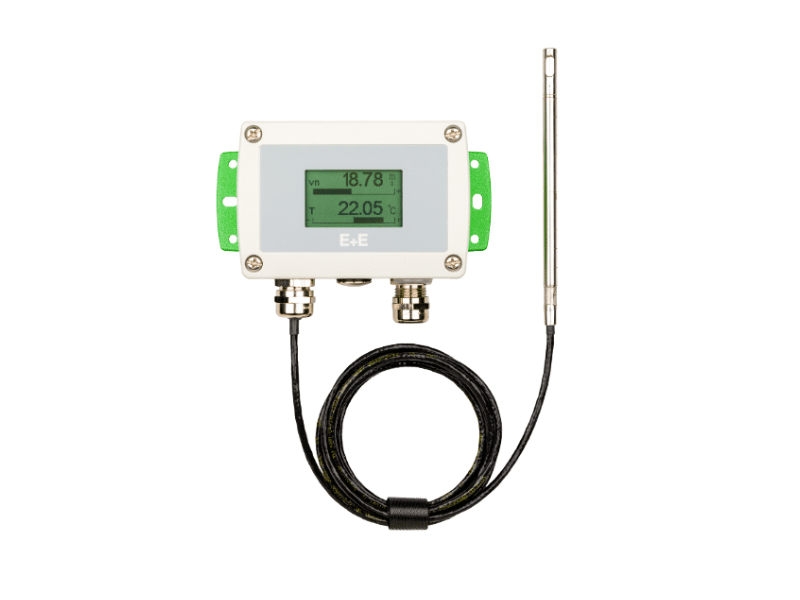

(Engerwitzdorf, November 2025) Developed and designed for demanding industrial applications, the new AVS701 from E+E Elektronik sets standards in terms of velocity measurement of air and gas flows. Maximum efficiency and process reliability through high-precision measurements, easy installation thanks to exact sensor positioning and an integrated process gas library characterize the sensor. The optional external pressure sensor also compensates for changes in ambient pressure. Equipped with a robust ceramic sensor element with a special coating and a stainless steel measuring head, high-precision measurement results are guaranteed even under extreme or corrosive conditions.

The visually and technically revised air and gas velocity sensor scores above all in the areas of accuracy and reliability as well as with a significantly simpler installation. It is optimized for demanding industrial applications in the measuring range of 0 to 40 m/s and -40 to +140 °C and is suitable for a wide range of applications – from use in the pharmaceutical industry to process monitoring in 3D printers. Increased efficiency in process costs and up to 60% faster assembly make the AVS701 the best choice in its performance class.

Thanks to a specially developed alignment crimping for the remote sensor, the AVS701 can be optimally positioned to the direction of flow with the included alignment tool. This precise positioning reduces unnecessary errors due to inaccurate installation and ensures accurate measurement results, which speeds up commissioning and significantly increases efficiency.

Optimum product quality due to the highest measurement accuracy

The AVS701 impresses with an exceptional measurement accuracy of ±1% of the measured value, and even ±0.03 m/s in the range of 0-2 m/s. This precision ensures a high level of process reliability, which is particularly important in sensitive applications such as cleanrooms and pharmaceutical production. The highly accurate monitoring of the air flow optimizes product quality and reduces waste. Changes in the process can thus be detected more reliably and thus prevented at an early stage. The long-term stability of the AVS701 also reduces maintenance costs.

Reliable accuracy even in the harshest environments

The AVS701 is equipped with a rugged thin-film ceramic sensing element protected by a rugged stainless steel transducer. A special coating on the sensor element protects against moisture or corrosive loads, such as Hydrogen peroxide or ammonia. This makes the sensor particularly suitable for applications in highly demanding environments such as the pharmaceutical sector or the chemical industry.

In long-term tests under increased ammonia exposure, all conventional sensors failed after an average of 440 hours and exhibited significant corrosion and electrical malfunctions. In contrast, the AVS701 remained fully functional even after more than 1,000 hours of testing – without corrosion and with stable sensor data.

Significant time savings thanks to intelligent gas adjustment

The AVS701 is equipped with a flexible process gas library that automatically enables gas-specific corrections. This function adapts the measurements to the properties of the respective process gas, which minimizes measurement errors and ensures high accuracy – even with changing gases such as CO2 or argon. The control system allows you to quickly switch to the appropriate throttle, which means that the sensor is ready for immediate use. This leads to considerable time savings and process reliability, as precise parameterization is carried out automatically and sources of error are reduced. The intelligent gas adjustment thus enables simple, efficient process control.

The AVS701 stands for precision and reliability in the measurement of air and gas velocities. With state-of-the-art thin-film ceramic technology, robust construction and easy installation, it is the ideal solution for the highest requirements in industrial environments.