An on-site inspection is part of the daily business of industrial valve manufacturers and plant operators alike. Safety-relevant components in particular, such as rupture discs or safety valves, must be tested by the manufacturer – this is often done by notified bodies like the TÜV. Many operators additionally conduct on-site tests at the manufacturer’s premises to ensure that the delivered products comply with the required specifications and performance features.

The coronavirus is making acceptance tests considerably more complicated and ultimately also riskier for all parties involved. The solution? Digital acceptance tests whereby the operator or inspection body observes the inspection of the products via video conference. The prerequisite for this is a precisely defined documentation process – as an operator, you know exactly what needs to be shown. In principle, these digital approvals are only recommended if dealing with well-known and trustworthy manufacturers. However, this applies across the board for safety-critical components, i.e. not just for acceptance tests.

Digital approvals using the example of a German rupture disc manufacturer

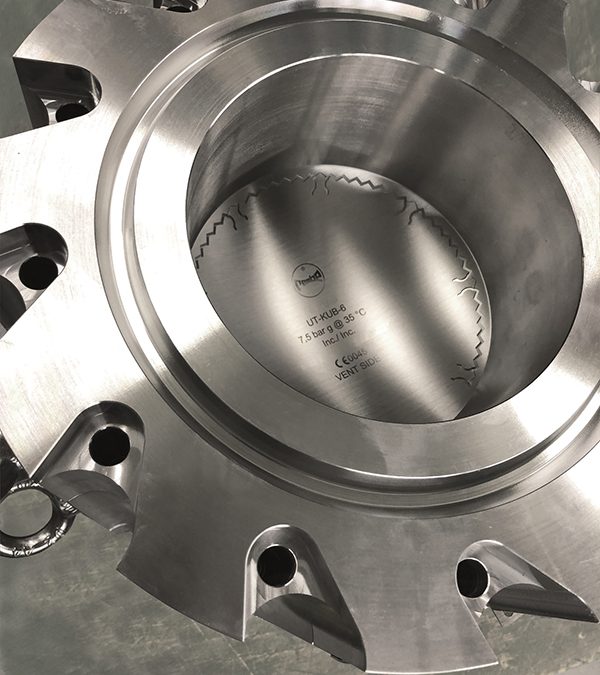

REMBE GmbH is an established player in the worldwide rupture disc market and is known for constantly breaking new ground. Probably the best known example of this from the company’s history is the development of flameless venting, which revolutionised explosion safety in the 1990s and is now offered by almost every market player. The reverse acting rupture disc KUB was also developed by REMBE engineers and has taken pressure relief via rupture discs to a whole new level. To this day, the performance characteristics of the KUB clearly stand out from most other products in terms of achievable burst pressures, tolerances and the robustness of the rupture disc.

While the company’s customers used to travel from all over the world to Brilon in North Rhine-Westphalia for acceptance tests, the coronavirus has put a stop to this practice. Alternative approaches had to be found – such as the REMBE Digital Audit. From small-scale burst tests or PMI tests to large-scale acceptance tests for power plants lasting several days, as well as certification audits by notified bodies, everything was included from day one. On average, we carry out two to three digital approvals per week. For more complex acceptance tests we provide the option to carry out a trial run of the approval process, thus enabling the buyers of REMBE products to gain an understanding of the likely outcome and to define any additional requirements if necessary.

“At the beginning of the pandemic, performing acceptance tests digitally was uncharted territory for us as well, but it is now part of our everyday work. The effort is of course much higher, as it is necessary to clarify in advance very precisely what the customer wants to see and all cameras and additional equipment must be positioned accordingly. In the case of larger approvals or certifications by notified bodies, we carry out a pre-test to ensure that everything really is exactly as it should be,” explains Stefan Penno, managing director of REMBE GmbH.

In addition to traditional acceptance tests, the REMBE Digital Audit Service also offers burst tests, technical inspections such as hydrostatic tests, factory inspections and installation support.

How can you benefit from professional digital approvals ?

- By saving time and money – no more travel time or expenses

- By safeguarding the required documentation – full digital documentation is provided, including images and sound

- By acting globally – your colleagues and partners at other locations around the world can participate in acceptance audits and tests, even at short notice

Fig. 1: REMBE is not only known as a supplier for special solutions but also for customer focused services worldwide such as digital audits.

About REMBE – the REMBE Alliance introduces itself

Most people associate REMBE with REMBE GmbH Safety + Control, the specialist for explosion safety and explosion venting worldwide. The company offers customers cross-industry safety concepts for plants and equipment. All products are manufactured in Germany and meet the requirements of national and international regulations. REMBE customers include market leaders in various industries, including the food, timber, chemical and pharmaceutical industries.

The company’s engineering expertise is based on more than 45 years of application and project experience. As an independent, owner-managed family business, REMBE combines expertise with the highest quality standards and is involved in various specialist committees worldwide. Short coordination paths allow for quick reactions and customer-specific solutions for all applications, from standard products to high-tech special designs.

In addition to REMBE GmbH Safety + Control (www.rembe.de) with approx. 250 employees worldwide, headquartered in Brilon (Hochsauerland, Germany), and numerous subsidiaries worldwide (Italy, Finland, Brazil, USA, China, Dubai, Singapore, South Africa, Japan), four other companies operate under the REMBE umbrella brand:

- REMBE Research & Technology Center GmbH (rembe-rtc.de)

- REMBE Advanced Services + Solutions GmbH (rembe-services.de)

- REMBE Kersting GmbH (rembe-kersting.de)

- REMBE FibreForce GmbH (argusline.de)

Press contact

sandra.drawe@rembe.de